Three factors affect aluminium's machinability

Aluminium is a relatively easy material to machine. It is also relatively easy to excel in this work, as long as you understand the three factors that affect the machinability of the metal.

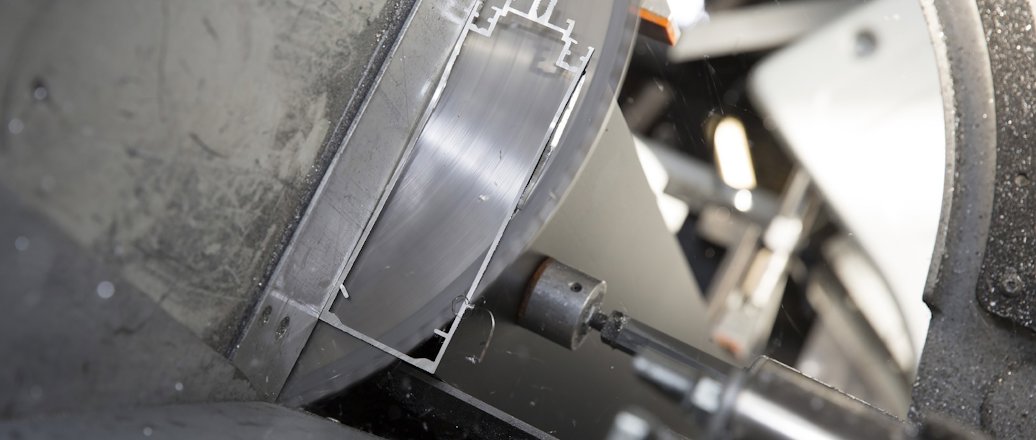

The first factor is the actual machining process. This includes the type of equipment, the cutting tools and cutting speeds, the feed rates and the lubricants to be used.

The second factor is the metal itself. I’m talking about the specific aluminium alloy and its temper, microstructure, and the uniformity of its mechanical properties. It is what is inside the metal that counts when it comes to consistency in machining.

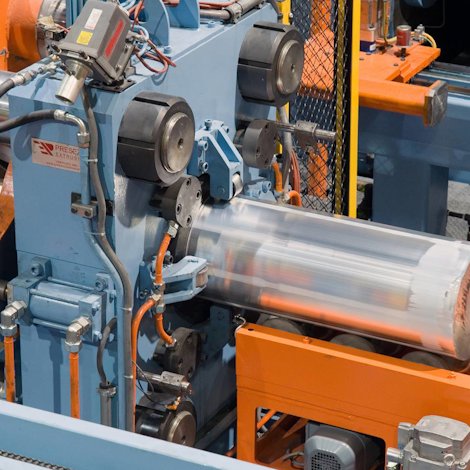

Material processing is the third factor. This involves the alloy chemistry and heat treatment, the extrusion process controls, the reduction ratio and die design, and the press used to extrude the aluminium.

Chipping characteristics in aluminium machinability ratings

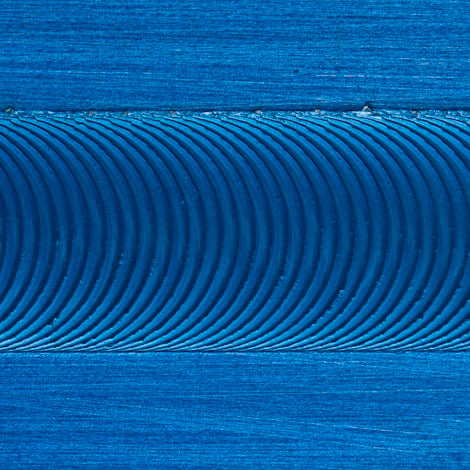

Machinability ratings for aluminium are based on chipping characteristics and are useful for specifying tool forms. Because of the volume of chips created while machining aluminium, the form of the chips is significant.

In general, when machining aluminium, you want to generate short, tight chips that do not interfere with tooling and which do not damage the surface of the part.

Machinability ratings for aluminium alloys specify the expectations for chips and surface finish:

- A-rated: Very small chips, excellent surface finish

- B-rated: Curled or easily broken chips, good surface finish

- C-rated: Continuous chips, good surface finish

- D-rated: Continuous chips, satisfactory finish

- E-rated: Long, continuous chips, difficult to maintain finish

Shorter chips with harder and stronger aluminium alloys

Normally, the harder and stronger the aluminium alloy, the shorter the chips. This also means that pure aluminium and soft wrought alloys are going to produce extremely long chips. If you are planning to machine such alloys, then you will need to take corrective measures ahead of time, like adding chip-breakers to the tools.

Aluminium alloys that are best-suited to machining contain alloying elements with low melting temperatures. This helps in the formation of the preferred, shorter chips.

Interested in learning more aluminium solutions for your products?

If you are interested in learning more about using aluminium solutions for your product designs, then contact Hydro and we will put you in touch with the right expert.