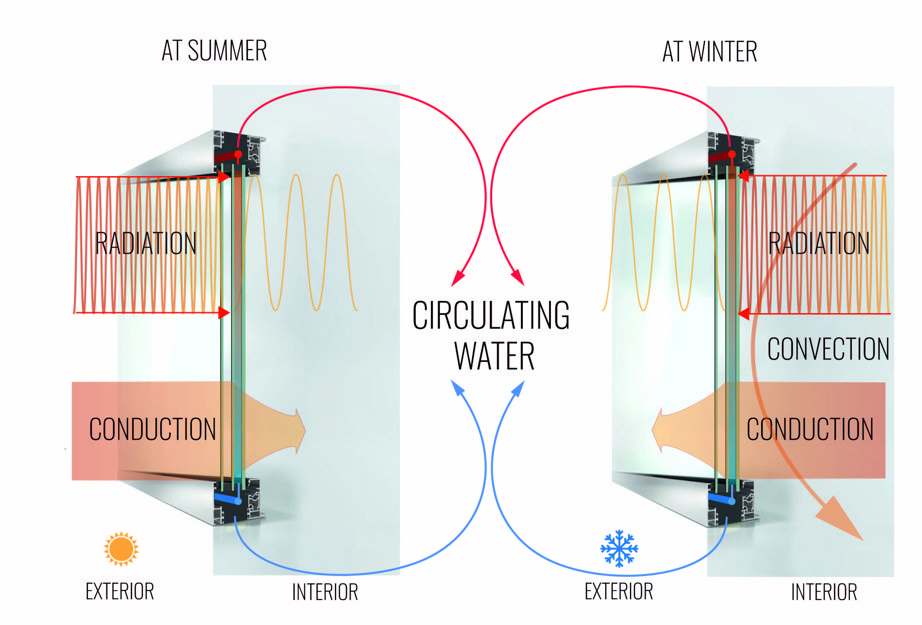

At Water-filled Glass Ltd and Loughborough University, we’ve developed a window that replaces the traditional insulating gas layer (usually argon) with clear, circulating water. The idea is simple: in the summer, the water absorbs the heat before it gets in. In the winter, it absorbs the heat before it escapes. The heated water circulates through a simple system connected to a heat exchanger, transferring energy in a way that's up to ten times more efficient than heating or cooling air.

The result is a window that delivers:

- Significant energy savings (up to 70% in heating and cooling, depending on climate)

- Better thermal comfort throughout the year

- Reduces the need for shading

- Better acoustics

- No loss in transparency or aesthetics

It’s just a better window.

The inspiration came during my years living in Japan, where the bath culture is strongly embedded in their customs, with onsens (hot springs). I was inspired by how powerful water can be in terms of comfort and thermal regulation. So that led me to the question: could water act as a thermal buffer in buildings?

Designing with aluminium and industry partners

The reason we chose to integrate our technology into an aluminium frame has to do with our holistic approach, one that considers the full circularity of the product. Turning to aluminium seemed like a natural fit, as it can be endlessly recycled and reused in a consistent way throughout the product’s life. We collaborated closely with WICONA, who at first thought the idea itself was kind of crazy. Even though façade systems are traditionally built to keep water out, we discovered that adapting frames for this new purpose was surprisingly feasible. It involved adding piping channels and drilling for circulation, but nothing that couldn’t be done with existing technology. The partnership has allowed us to build a system that doesn’t just work in theory but can be manufactured at scale.

A window you can feel

We are showcasing Water-filled Glass at the Architecture Biennale in Venice this year, and one of our goals is to make the experience of the window feel intuitive. We have installed a pylon with two sides, one with a normal insulated glass unit, and one with Water-filled Glass. As soon as visitors hover their hands over the two sides simultaneously, they immediately understand the difference in energy regulation and performance. The Water-filled Glass side is cooler, whereas the side with the conventional glass, when exposed to radiation, feels much warmer.

Glazing contributes significantly to operational energy loss

The real value in Water-filled Glass is two-fold. The EU aims to retrofit 16% of buildings, but as of today we’re doing less than 1 percent of deep retrofits per year. The challenge is that retrofitting windows is disruptive. You remove the old ones, install new ones, move out tenants, cancel contracts, apply for permits… It’ a hassle. Water-filled Glass solves this by being usable as secondary glazing from the interior, meaning you can keep the existing window and sandwich this technology inside.

Secondly, existing glazing innovations like smart glass and electrochromic glazing have a high carbon footprint, and with windows lasting only 30 to 50 years, it’s not always clear if these systems will recover the environmental cost of their production. Water-filled Glass doesn’t have this issue, as it is far more energy efficient, and the embodied carbon is lower because it uses water. The water circulation system in Water-filled Glass is also connected to your mechanical system, enhancing the performance of technologies like heat pumps.

We believe this can unlock a massive potential for reducing global carbon emissions.