Anodized aluminium for designer facades

When anodizing aluminium, we might use new brush techniques, airbrushes or gradient dipping. This gives the material a luminosity that you can’t get with a powder coat or paint.

I grew up surrounded by aluminium in the Neal Feay Studio, which my grandfather Neal F. Rasmussen started in 1945. By the age of eight I was doing silk screening and at 13, I could handle programming in technical machine code. I joined the company full time in 1987.

My grandfather made everything in aluminium, from panels to gift items and bracelets. He used Anofax, a multi-colored anodizing technique, which he invented. Since then, we have been refining our anodizing skills and collaborating with architects, designers and artists who have really pushed us to overcome limitations. We have created new finishing techniques that we would never have discovered if we hadn’t been challenged to make things like aluminium clouds!

New anodizing techniques

Architects, designers and artists from around the world have discovered the beauty of anodized aluminium through the Neal Feay Studio. We anodize everything from earphones that are the size of a coin, to 200 square-meter building facades. Our creative efforts continually prove there are no limits to what can be achieved with anodized aluminium.

Architects have fallen in love with anodized aluminium.

It’s an attractive material that is easy to use as a facade and on tight building corners. The beautiful black facades we make for an international perfume and cosmetics chain use modular aluminium rectangles so that both big and small stores get a uniform look. There is extremely low waste as we use a reductive machining technique where we take a raw extrusion and completely machine it so there are no extruded surfaces.

I know that people working in construction are often hesitant about using aluminium, but once they’ve constructed an aluminium facade for the first time, they are quickly won over. The precision of the machined pieces makes their job so easy.

Exciting ways to use anodized aluminium

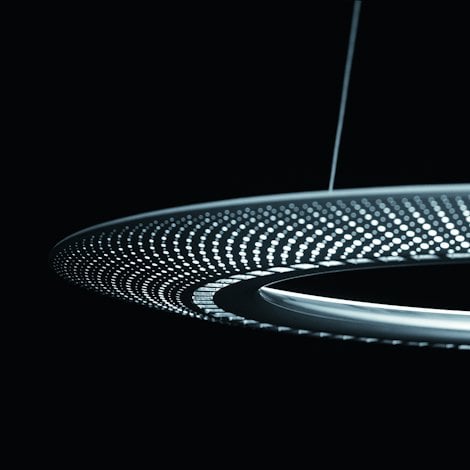

Holly Hunt’s striking interior design pieces, such as the Ember chandelier, is just one example of how to use anodized aluminium in an exciting way. The multi-faceted chandelier is anodized in gold and black, machined on a four-access mill and lightly polished.

At Neal Feay, we want to push things further all the time and we ask the same of our vendors. We want our end result to be something that no one has seen before and we want our extruder to think the same way. Hydro thinks like that too, which is a huge bonus for us.

For more information about Neal Feay Studio: www.nealfeay.com