It all started with meeting new people. When I first met the designers at Front, we agreed we wanted to challenge ourselves by doing something new together. We quickly realized that there was one staple piece of furniture that we did not have in our portfolio – the archetype cast iron garden bench. We wanted to use aluminium instead of iron and see how we could create the classic with a modern twist.

New material for a classic shape

We kept the classic shape, but by choosing a new material and a new production method we achieved a different look. We also learned a lot along the way.

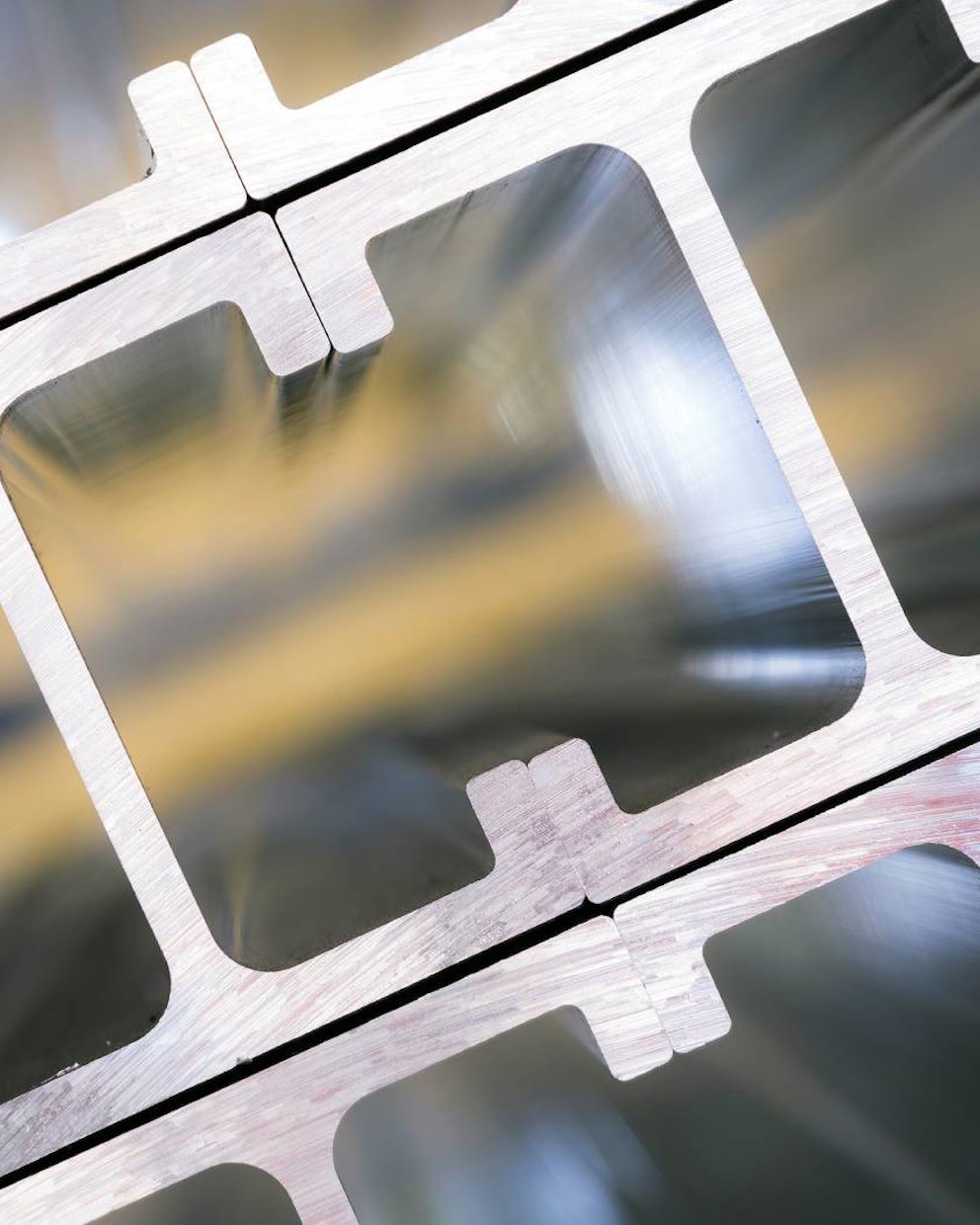

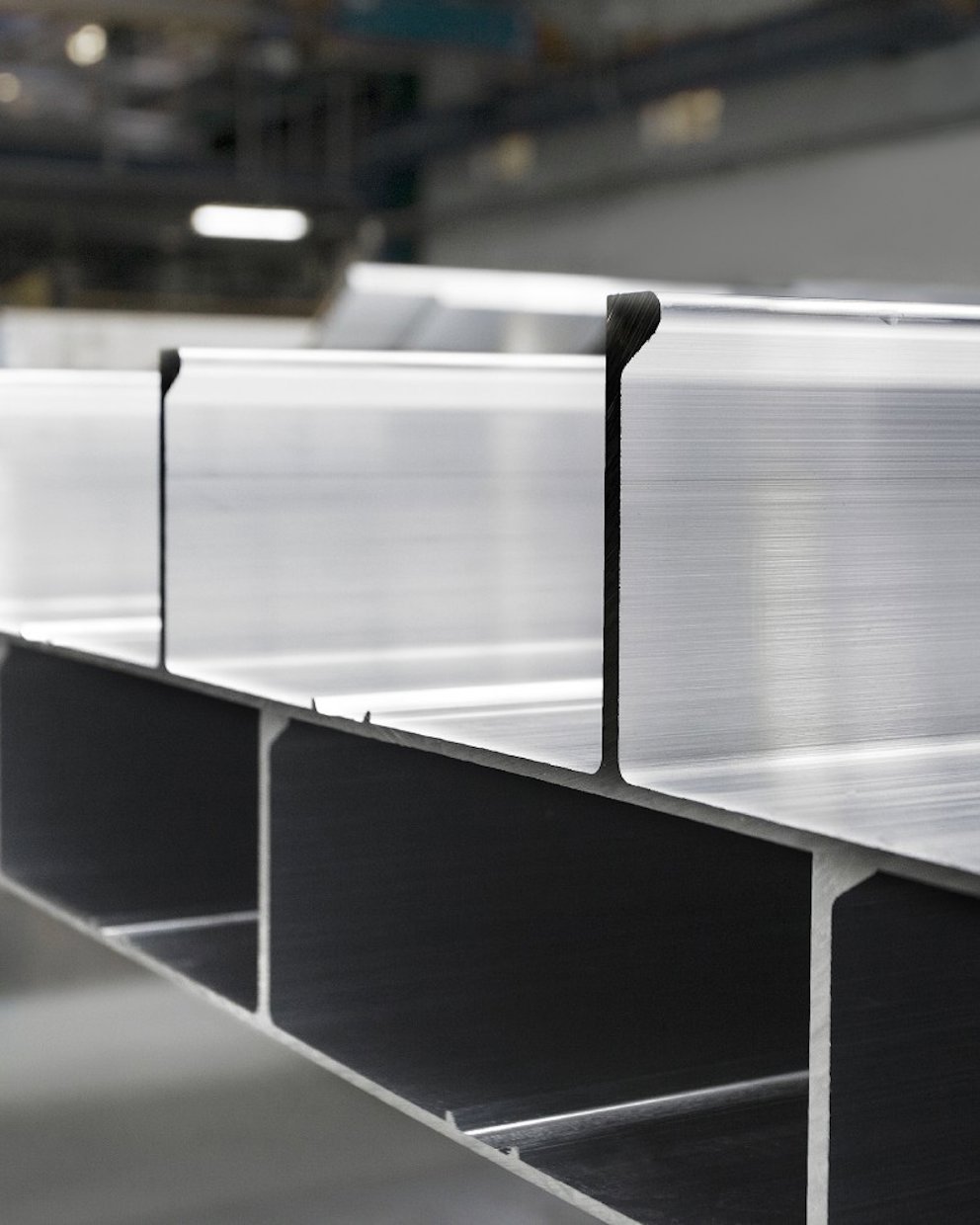

We visited aluminium experts at Hydro Vetlanda in Sweden to learn more about the material properties of aluminium. In the early design process, we had been overly optimistic about the necessary strength and the preferred slim design working together in a welded shape. The shape needed to be sleek and elegant, but with the necessary durability to last for years in an outdoor environment. Then the opportunity to use extrusions came up. By making extruded profiles specifically designed for our purpose, we had the opportunity to tailor the shape to meet our needs for a strong bench that looks light and elegant. Could we create a profile which allowed shape and thickness to work together?

Uniquely designed extruded profiles

Hydro Extrusions in Magnor helped create an extrusion tool from our sketch and pressed the uniquely designed extruded profiles. To shape the profiles, Lena Metall pushed their machines to the maximum to create the curves we wanted. We collaborated closely with the factory to create the optimal result and achieved the sculptural form as an outcome. This meant we were able to create a profile that is thicker around the center in a sort of soft half moon shape, creating a very strong material.

It turned out beautifully. The simple profile looked very cultivated, almost as if it was casted, but the sculptural shape comes from a profile. Today we have learned how to shape the extruded material in our own factory.

This is the exciting part of being a designer, the choice of material played a key role in shaping the final product. Everything has also gone very fast, from idea to product and delivery of the final extrusion cast and materials thanks to a great collaboration with the fantastic designers in Front and technical aluminium experts.

It all began with a meeting and a challenge. Now, people can rest or meet friends on the Folk park bench, enjoying the timeless joy of being together outside. Vestres modern classic has even received the DOGA Award for Design and Architecture.

This article was originally published on Shapes in February 2020. It has been updated with pictures from The Plus, which opened in 2022.