How to design curved aluminium profiles

The extrusion process takes advantage of the formability of aluminium, a unique property which ensures that aluminium profiles can be bent very well. But this is not the case for all profiles. What do you need to know when designing curved aluminium profiles?

We use curved aluminium profiles in architecture, construction, transportation and machine building, and in consumer products such as prams, lighting solutions and caravans. Just having the possibility to integrate such profiles into a construction gives a designer more freedom of design.

Still, there are some things you need to know before designing curved aluminium profiles.

Alloy and condition considerations affect bending

Let us begin with a look at 6xxx-series aluminium alloys.

Alloys from this series are often chosen for bent aluminium profiles, due to the good ratio between strength and deformability. However, you need to understand that alloys which offer higher strength, such as EN AW-6082, are more difficult to form.

Heat treatment also makes profiles more difficult to bend. Consequently, it is generally better to bend in T4 condition and then age to T6 afterwards.

Effects of additional functions on bending and extrusion design

You also can add functions in extruded aluminium profiles, such as click connections, screw channels and cooling fins – things that can greatly simplify the production and assembly of a product.

When adding such features, you as designer should consider how these features affect bending.

For instance, because the thickness of different parts of an extrusion affects the bendability of the section, uniform wall thicknesses offer advantages for both extruding and bending. The same goes for symmetry: When creating the profile, you should try to design symmetries in the profile as much as possible.

Extrusions with a wall thickness of 2-to-15 mm can be bent and have small bending radii of 300 mm. These are possible. But the bending options differ per profile and need to be viewed separately.

Anodizing and powder coating only after bending

Curved aluminium profiles can also have an aesthetic function. The degree of finish and possible surface treatments can influence the choice of process and use of special tools.

It is advisable to anodize or powder coat the profiles only after bending, because small hairline cracks can occur in the anodizing or powder coating layer during bending.

Differences between most common bending processes

The most common processes for bending aluminium extrusions are roll bending, stretch bending and mandrel bending. The process you choose should depend on the type of profile you design, as well as its application and production numbers.

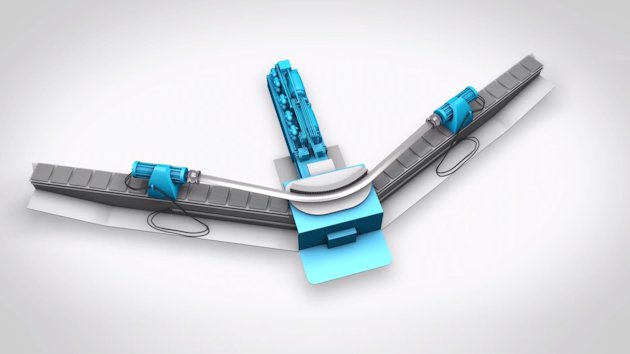

- Roll bending. This is in many cases the most flexible and cost-efficient method. The profile is guided along three adjustable rollers and then bent step-by-step in controlled fashion into the desired radius. Roll bending is ideal for profiles with complex cross-sections and different radii. The rollers are tailored for a certain type of profile so that they guide and support the profile perfectly.

- Stretch bending. In this process, the profile is firmly clamped at both ends. The machine stretches the profile, then pulls it around a bending mold. Due to the constant tension, cross-sectional distortion is kept to a minimum. This method is suitable for profiles with high demands on surface quality. The cost of a bending mold for this process is relatively high, which makes this process interesting for higher production numbers.

- Mandrel bending. When bending a relatively thin-walled profile in a very small radius, the risk of cracks and swelling increases. To prevent this, the profile can be bent by means of mandrel bending. Mandrel bending is accurate, fast and delivers a constant quality. It is suitable for medium and large-series production.