Smart design can reduce risk of surface flaws

Even at the design stage, it is possible to reduce the risk of surface flaws on aluminium profiles. This is what you need to consider.

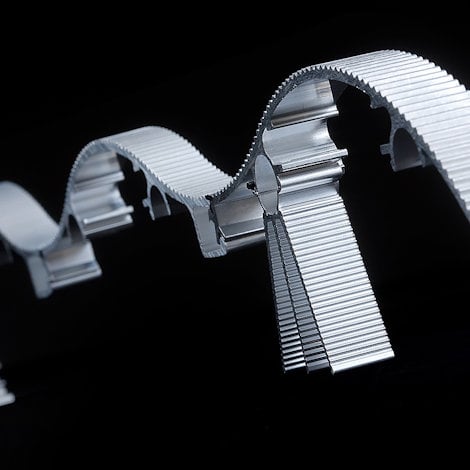

Sharp transitions between thick and thin areas of material may have an effect on surface finish, especially after anodizing. Using generous radii, ribs and decorative ridges generally also improves the surface appearance.

The surface quality of an extruded aluminium profile depends on the condition of the die, the profile design, production conditions and choice of alloy.

Various types of flaws, such as extrusion lines that are process-related, are recognized and occur when the profile emerges from the die. These are always to be expected.

Know your surface quality needs in the end product

Information on a profile’s visible surfaces is important. Besides being used in surface evaluation, this information is used in the construction of dies and when preparing profiles for anodizing or painting.

Anodizing results in a general improvement in surface quality.

Please note that sample profiles are not representative in terms of surface finish and material properties. They should only be used for checking dimensions and similar.