How to ensure full transparency regarding the footprint of aluminium products

Pre-consumer scrap aluminium is usually considered equivalent to post-consumer scrap in life cycle assessment studies, where it is classified as waste, with no associated environmental burden. Should this be the case? Because there are some major differences between the two types of scrap.

First, post-consumer scrap has already lived its life as a product, and the greenhouse gases related to the production of the aluminium were likely emitted several decades ago. Not so with pre-consumer scrap, which has never had a life as a product.

Secondly, waste material is generally defined as having no monetary value. In fact, the mitigation costs associated with waste material usually have a negative impact on business, meaning that they should be reduced, removed or avoided whenever possible.

This is not the case with pre-consumer scrap – also called process scrap or industrial scrap. There are normally no extra costs required to discard pre-consumer scrap. On the contrary, the scrap metal can be sold externally to recyclers, for example, meaning the material has a positive financial value.

Two methods of calculating the carbon footprint of aluminium scrap

However, as I mentioned, pre-consumer scrap is usually considered equivalent to post-consumer scrap in life cycle assessment (LCA) studies. Why?

There are several valid LCA methods for carbon footprint calculations of pre-consumer scrap, and the main international standards (ISO 14040-44, ISO 21930, EN 15804+A2) do not provide clear guidance about a mandatory approach. Two methods are regularly used:

- The cut-off approach. Here, the footprint follows the main product because there is no environmental burden for the scrap.

- The mass-based allocation approach. In this case, the footprint follows the material, with the burden shared between every output (ingot and scrap).

The main reason the two scrap types are considered equivalent is because the cut-off approach is easier to put into practice. Applying the co-product, mass-based approach implies the ability to fully trace the scrap. This is not as easy.

Ultimately, while both approaches are valid from an LCA accounting point of view, they lead to very different results.

Freeing pre-consumer aluminium scrap from its production burden

So what do we do? Should we choose one method over the other? Is there a right method?

Well, it is a simple thing to say that the cut-off approach could hinder the development of the circular economy. By not providing post-consumer scrap with a carbon footprint advantage, it could incentivize the use of pre-consumer scrap due to its relative ease of access. I mean, in terms of sustainability, the primary focus ought to be on reducing and avoiding scrap in the production process.

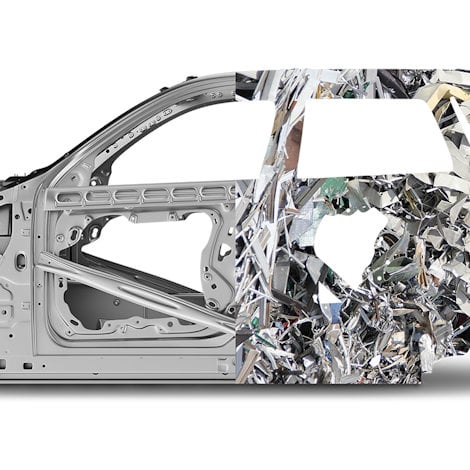

In the larger perspective, freeing pre-consumer scrap from its production burden does not contribute to a more circular economy. Instead, it positions pre-consumer scrap as the most desirable source of aluminium scrap – and post-consumer scrap as the least interesting source. It should be just the opposite.

Remelting pre-consumer scrap is ultimately a question of process efficiency, while recycling post-consumer scrap supports the circular economy and innovative approaches to material sourcing, such as urban mining, that can minimize the need for processes with the largest carbon footprint, such as primary aluminium production.

Both the cut-off and mass-based approaches

While I personally believe that the mass-based allocation approach is a good way to get a realistic picture of the carbon emissions and incentivize a circular economy, in the absence of an official consensus, we should offer data to calculate with either method because transparency is key.

We need transparency to build trust among those who buy our aluminium products and not least among end-consumers who are getting more and more advanced in their understanding of sustainability.

It is no longer enough to just say that your product is “sustainable” or “recycled.” You have to explain what that means and openly share the data, so they can be verified.