Why structural projects need ductile metals like aluminium

Ductility is a major safety consideration for structural projects. Let me explain to you exactly what I mean by ductility, and why aluminium is a metal you ought to consider for such projects.

As you probably already know, ductility is the ability of a metal to receive permanent deformation without fracturing. Metals that can be formed or pressed into another shape without fracturing are ductile.

In general, all metals are ductile at elevated temperatures. At room temperature, however, there is another story. Metals that only can receive a small amount of deformation before fracture are classified as brittle – essentially the opposite of ductile.

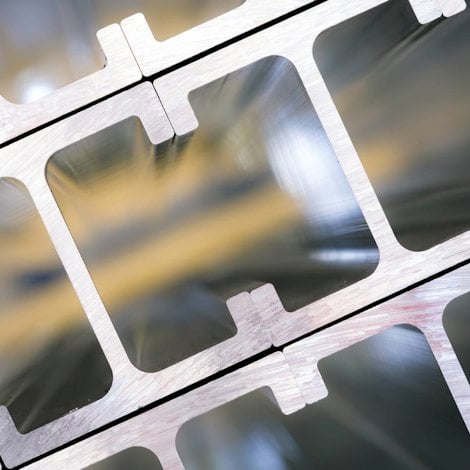

Ductile aluminium for structural projects

Ductility plays a key role in formability, because excessively brittle materials may not be able to be formed successfully. When you wrap your sandwich in aluminium foil, for example, you are taking advantage of the ductility, because the foil is shaped around the sandwich and stays in that form without breaking.

Now imagine doing the same thing but with an equally thin sheet of glass. If you bend it too much it will break, and if you bend it too little it will only spring back.

This is incredibly important when it comes to safety in structural projects, like bridges. It is not like you design or construct your bridge to deform, but in the event of an accident or overload situation, the last thing you would like is sudden rupture. Ductility allows structures to bend and deform to some extent without rupturing. High ductility is critical in applications such as metal cables and structural beams.

Gold, silver and platinum are ductile metals. So are most aluminium alloys. Cast iron is not.

How to measure the strength of a metal

You can measure the strength of a metal by examining its tensile and impact strength, as well as its ductility and hardness. There are two ways to measure ductility:

- Percentage elongation measures the length that a metal deforms as a percentage of its original length, after it is pulled to failure during a tensile test

- Percent reduction measures the narrowest part of the cross-section of a metal specimen following a tensile test-induced rupture

Ductility also can be dependent on temperature, meaning that you should take into account the temperatures the metal will be subjected to in your application. Some metals – not aluminium included – have a ductile-brittle transition temperature.

Low hardness in ductile metals

You can also measure hardness. Hardness in this discussion is the ability of a metal to resist indentation. It is important when your metal needs to be able to withstand forces without depression or denting. And it is important when you need a metal that is subjected to forces and objects that may cause wear, or abrasion.

Today, we can increase the hardness of a given metal with special processing, such as heat treating or work hardening.

Because hardness is often inversely related to ductility, the ductile metals that I mentioned above will normally have relatively low hardness.