Adhesive bonding in multi-material concepts

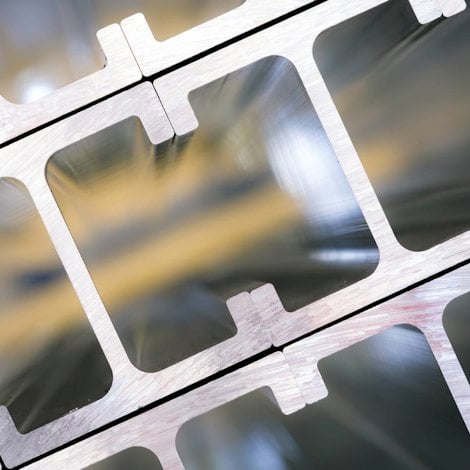

An adhesive that can bind to several different materials is an interesting alternative for product developers working with aluminium.

There are many types of joining methods. Adhesive bonding is one. It is a joining method that can result in high-performance joints when aluminium is joined to aluminium as well as with other materials.

If you as a designer choose adhesive bonding as the joining method for your product, then you need to know that you are selecting more than only a specific adhesive. You are choosing a whole adhesive system.

This includes mechanical properties, surface treatment, mechanism of cure, application technique, joint configuration, quality assurance, corrosion properties, and aspects related to health, safety and the environment. And more.

Adhesives spread load over large areas

An adhesive can form a tight bond over the entire overlap area, spread load over large areas, and keep the joining processes at moderate temperatures.

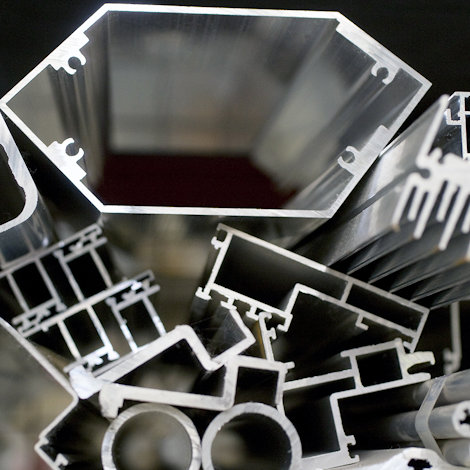

The biggest difference between adhesive bonding and joining methods such as soldering and fusion welding, is that the additive that creates the joint is made of plastic/polymer, rather than molten metal. This permits the joining of different types of materials that could not otherwise be reliably joined. For example, welding and soldering do not work when joining metal to plastics.

Heating a material, as in soldering, brazing and fusion welding, can reduce strength and cause deformation. This does not occur with adhesive bonding, due to the low or moderate temperatures involved in the process.

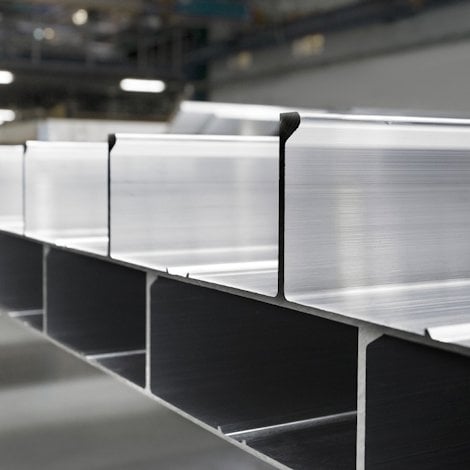

Joining thin materials

As I mentioned, an adhesive joint can carry load over larger areas when compared with “spot” mechanical joints such as rivets, clinches and screws, which can have relatively high local stress. The strength, stiffness, energy absorption and durability of a correctly dimensioned adhesive joint will therefore be better.

Uniform load distribution can also enable a reduction in material dimensions. In general, the advantages of adhesive bonding become more apparent when joining thin materials.

I will talk more about the adhesive bonding of aluminium in the months to come, because joining is an important part of product development, and adhesive bonding can be a good alternative for multi-material concepts and solutions.

Interested in learning more?

Check out this in-depth white paper on adhesive bonding of aluminium.