How to prevent pitting corrosion in your aluminium designs

The most common type of corrosion on aluminium is pitting corrosion. Pitting is primarily an aesthetic problem, but it is unpredictable and could lead to performance failure when surface appearance is critical. These tips will help you avoid pitting in your aluminium components.

Pitting is a classic type of corrosion in seawater environments and in humid environments where salt is present. The most common types of salts in atmospheric exposure that will cause pitting are based on chlorides or sulphates. In case of alkaline or acidic salts, the pitting rate will further increase.

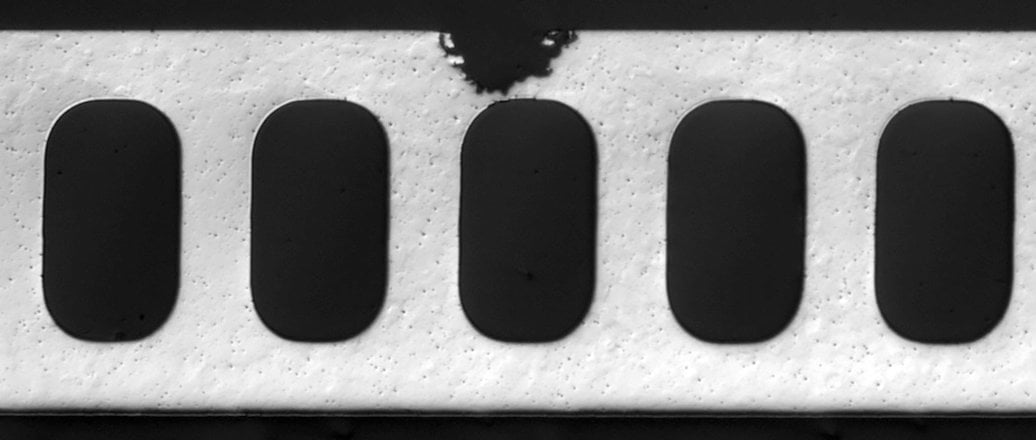

The corrosion generally appears as extremely small pits, or holes. These pits, in the open air, will in most cases only reach a minor fraction of the metal’s thickness and hence not affect the strength of the material.

Pitting has a local character and is randomly distributed over the surface. The size and depths of the pits have a stochastic distribution over the attacked surface.

In applications where the surface appearance and aesthetical properties are important, pitting can be critical – and must be avoided.

Tips on how to avoid pitting corrosion

- Painting, anodizing or any surface treatment that forms a coating on the aluminium surface will protect the surface from pitting attack. In applications when you want to preserve the aluminium look and still have a surface resistant to pitting, a clear coat or thin anodic coating would be suitable surface treatments.

- Pitting on aluminium profiles or sheet surfaces may also be kept to a minimum by regular cleaning of the surface. For cleaning, use mild alkaline or acidic detergents.

General recommendation to reduce corrosion in constructions

- Avoid angles and pockets in which water can accumulate. Instead, use a shape that promotes draining.

- The risk of dirt build-up is reduced with increased radius in corners.

- Stagnant water is avoided by suitably inclining the profile and/or providing drainage holes (recommended minimum 8 mm). This is to avoid capillary forces to preserve water in the construction.

- The ventilation of “closed” constructions reduces the risk of condensation.