Aluminium profiles that are used in buildings, cars, electronics and many other applications often require a coated or anodized finish. Anodizing is an electrochemical process. It increases the thickness of aluminium oxide in the surface, thereby improving the product’s durability, corrosion and wear resistance. It is a robust process that was first patented more than 100 years ago.

Microstructural defects change etch rates and oxidation

Aluminium parts go through a series of steps before the actual anodization process, which include cleaning, pretreatment, the application of electrical current for oxide growth, colouring and/or sealing.

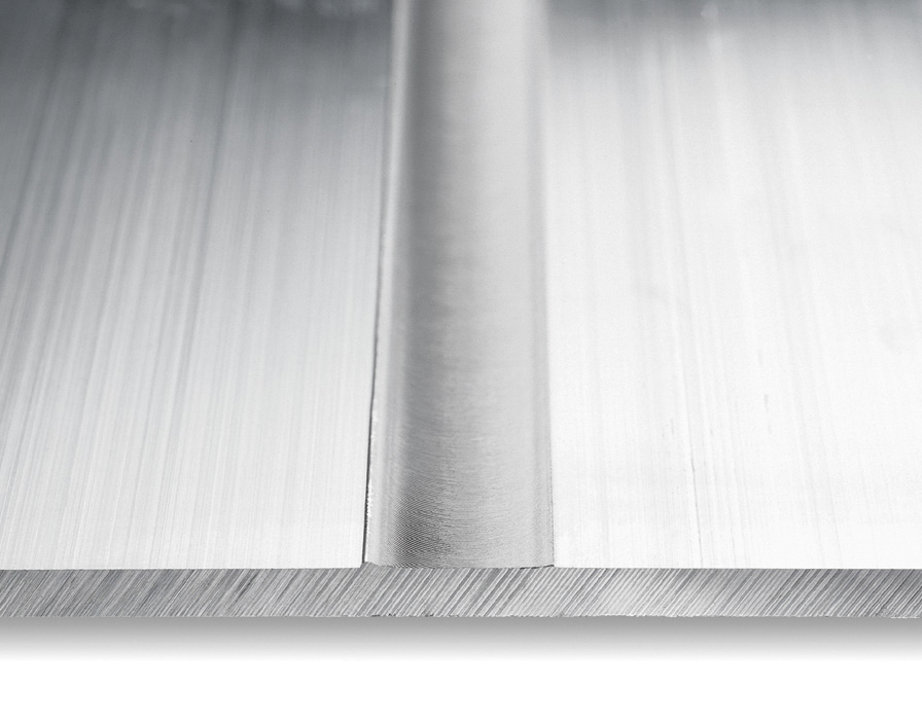

During pretreatment, the metal is exposed to alkaline or acidic solutions in order to remove the surface layer that is formed during extrusion.

The etching and oxide-growth steps are preferential dissolution of aluminium, driven by the electrochemical potential difference in the microstructural features of the alloys. Meaning that the unique structures within the alloy influence how and where the aluminium dissolves.

Microstructural defects will change the etch rates and oxidation. This implies that an underlying issue that was not visible before the anodizing process, may therefore be magnified and become more visible, especially during etching.

Process steps can impact surface quality

The etch response, due to a difference in microstructure or other, leads to differences in the way the light is reflected from the substrate, or base material. And because the anodic aluminium oxide layer is transparent, or clear, it reveals the underlying etch structure of the substrate.

That said, in many cases, the surface treatment may remove the evidence of the non-uniformity, leaving only unusual etch morphology on the surface. This makes investigating the defects on the anodized surface a task that requires understanding of the various process steps and formation of the surface layer.

Here are the steps that may impact the surface quality of an anodized aluminium profile:

- Casting extrusion Metal cleanliness, surface quality and microstructure during solidification, homogenization and housekeeping.

- Storage before extruding, extrusion tool and parameters, post-extrusion processes, housekeeping and cleanliness, transport to anodizer.

- Surface roughness, presence of burrs, cleanliness etc.

- Anodizing. Storage before anodizing, pretreatment and anodizing parameters, post-anodizing processes, housekeeping, transport to end-users.

- End-user. Storage before installation and cleanliness.

- Environment/surroundings during

The best method for addressing the root cause and eliminating an issue, in this case, a surface defect, is to understand the manufacturing steps prior to anodization. And a good way to understand these steps is to have a strong collaboration between customer and supplier.