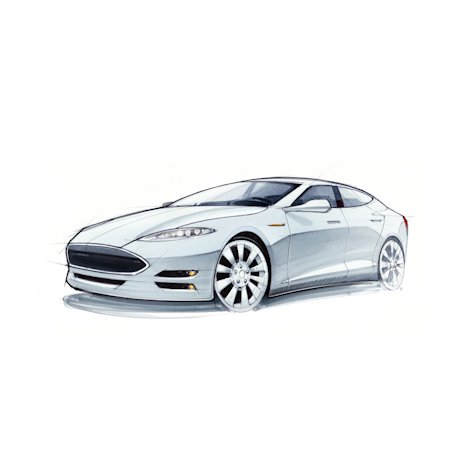

Why aluminium in cars is common sense

In the quest of making lighter cars, aluminium and other lightweight materials are replacing steel. However, not all components of the car can be replaced by these materials. Let’s look at the right usage of aluminium in cars.

Putting cars on an aluminium diet makes it possible to achieve weight savings of up to 50 percent compared with other materials in most applications. It does not come at the expense of safety, either. The average European car contains 140 kilograms of aluminium. This is more than 300 pounds, and the amount has increased significantly over the years, just as the average weight of a passenger car also has increased significantly since the 1970s.

The quest to make lighter cars has resulted from the direct connection between weight and fuel consumption, and the laws requiring improved mileage and reductions in carbon dioxide emissions.

In the short term, carmakers can replace steel with aluminium in a number of components without requiring major redesign. This would easily allow average kerb weights to be reduced by another 40 kgs. This figure also includes secondary savings that could be made as a result of the weight savings.

Here is a short list:

- Body panels (40 percent lighter car body than in steel)

- Heat exchangers

- Engine blocks

- Shock absorbers

- Wheels (up to 35 percent lighter than steel)

- Suspension parts (30-to-35 percent lighter than steel)

- Interior design and decoration

- Exterior details like roof rails

The drive train, brakes, fuel tank and crash safety systems also are parts that could be made smaller while still maintaining performance.

Green argument

Here is an equation that makes it easier to understand the importance of lightening our vehicles. Let’s say that a vehicle is driven 200,000 km. That’s around 125,000 miles. And let’s say the secondary weight savings total 20 percent. Each kilogram of aluminium gives an average weight saving of 1 kg, because steel would be twice the weight.

One kilogram of aluminium in a car reduces its carbon dioxide emissions by 19 kgs over the life of the car. If we include the production and distribution (wheel-to-wheel) of fuel, then we can say that a weight reduction of 100 kg in a car means a saving of 10 grams of carbon dioxide per kilometer, in other words 2,000 kgs during the lifetime of the car.