Using new technology to improve primary aluminium production

I am optimistic and forward-leaning when it comes to the future of the primary aluminium production process, and the exciting new ways we are improving this process.

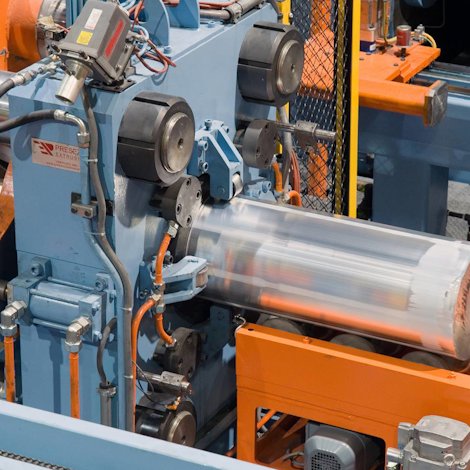

This is about utilizing best practice in all plants and across shifts, implementing new technology elements whenever we re-line and upgrade our existing plants, utilizing more automation and Industry 4.0 elements, and using digital twins in the control system of the smelter.

A digital twin is a simulation model of the electrolysis process, built on physics-based models, sensor data and advanced analytics. My company has such models implemented directly in the control system of the electrolysis cells at two of its primary aluminium production sites in Norway. The twin automatically controls temperature, alumina addition and acidity of the electrolysis cells.

Interested in learning more aluminium low-carbon products?

If you are interested in learning more about using aluminium solutions and low-carbon products for your product designs, then contact Hydro and we will put you in touch with the right expert.