Production tips for designers

Translate your designs into fantastic aluminium end products with the help of a few production tips and more accurate prototyping.

Any number of engineering and production issues need to be resolved before a product reaches the supplier. With all players getting in on the process at an early stage great designs will be made easier to manufacture, without reducing their attractiveness. The number of iterations on a design can also be reduced significantly with early collaboration.

Substantial production savings can be achieved by eliminating manufacturing steps where feasible, cutting down on waste, ensuring that the most appropriate material is used, and reducing expensive tooling by refining product designs with prototypes in aluminium.

Prototypes in aluminium

Prototyping offers many benefits, such as extremely accurate extrusion representation, tight tolerance control, reduced cost and quick turnaround time. An efficient way of creating prototypes is an industrial process called Electrical Discharge Machining (EDM) that can create prototypes from aluminium, rather than plastic or other materials. This gives designers and architects a much more accurate representation than is possible with 3D printing or other conventional prototyping technologies.

Understand the possibilities of extrusions

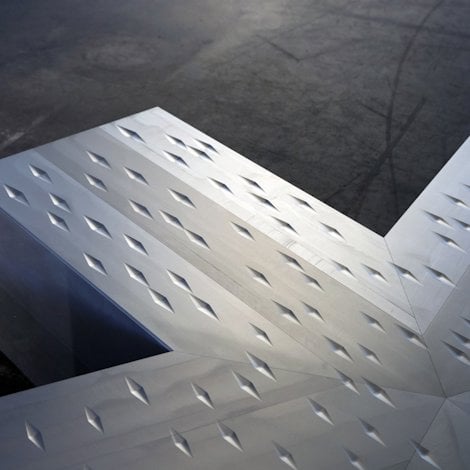

Versatile aluminium can be made into intricate forms with a variety of dimensions and shapes through the extrusion process. It is important to be aware of how smart extrusion design makes it possible to incorporate more functionality and features into a shape at no added cost (with no welding or joining needed). For example, by adding simple features to a profile such as screw ports, mating features, nut tracks, etc., a designer can easily increase the functionality of a component and remove secondary processing steps.

Typically, these extra features have an undetectable cost impact on the profile itself, but provide very direct cost savings.

Understand how to best assemble the product

There are infinite ways to add functionality to an extruded product. There are also multiple ways to assemble a product or fixture more easily, which adds up to a reduction in time and expense. It’s all about optimizing the production of a great design and getting more bang for your design buck.

Interested in learning more?

Hydro offers Electrical Discharge Machining (EDM) to create extrusion prototypes and provide feedback and performance analysis on a solution to help you get the best result before your design hits production.