Can low-carbon aluminium products answer automotive’s sustainability challenge?

I’m convinced that aluminium produced with a low-carbon footprint will push more steel and copper out of passenger vehicles. With low weight and complete recyclability, it reduces the use-phase environmental impact of vehicles, and its sustainable footprint will help you achieve your low-carbon emission targets from a life-cycle point of view.

The focus today is on reducing use-phase emissions, such as tailpipe emissions, by either increasing the efficiency of the vehicles or by using alternative drivetrain concepts in combination with a high share of sustainable energy sources. But other priorities are coming, fast.

When you look at the entire life cycle of passenger vehicles – and you should – you see that these developments lead to more relevance of the production phase of the car. This underlines the need to perform the ecological assessment from a life-cycle perspective in the future.

Highly competitive low-carbon aluminium

Using aluminium in cars, offers significant weight reduction potential compared to conventional steel materials. However, the production of aluminium usually leads to a higher weight-specific carbon footprint than steel.

The steel industry likes this argument when comparing its material to aluminium. But the argument is getting weaker.

Well aware of what the automotive industry needs, aluminium producers have been addressing the need for low-carbon aluminium materials with intensive research and development activities. These activities have led to the introduction of lightweight materials that are highly competitive in terms of carbon footprint and life-cycle analyses.

Hydro REDUXA 4.0 is an example. It is hydropower-based primary aluminium with a maximum carbon footprint of four kilograms of CO2 equivalents per kg aluminium. The industry average is more than four times higher.

Low-carbon aluminium compared with conventional steel grades

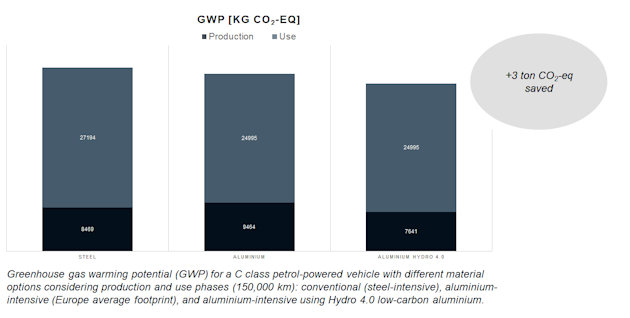

Together with the research institute fka in Aachen, Hydro carried out a study that outlines the impact of applying conventional and low-carbon aluminium in comparison to conventional steel grades on the Global Warming Potential of vehicles from a life-cycle perspective.

In this study, we considered two reference vehicles from different segments and with different drivetrains, and investigated the achievable weight reduction potential by the application of aluminium in a first step. Beside the primary weight saving achieved in the body, we also considered secondary effects, such as downsizing the engine or the scaling effects of the battery.

In our second step, we performed a life-cycle assessment for the different vehicle variants and compared these to each other in various scenarios.

The results of the study show that the lightweighting by using aluminium can significantly reduce the use-phase environmental impact of vehicles and can help automotive OEMs achieve their low-carbon emission targets.

By using low-carbon aluminium such as Hydro REDUXA 4.0, you can achieve a footprint reduction also in the production phase as compared to steel. Hence, this is the most attractive solution from an environmental sustainability perspective for all vehicle configurations.

This sustainability improvement in the production phase may seem like a paradox, since steel does have a lower carbon footprint than Hydro REDUXA 4.0 as measured per kilo material. However, due to the weight saving caused by aluminium, obviously less kilos of material are needed in the vehicle – and this more than compensates for the difference in footprint when considering the impact per kilo.