How we can achieve zero-emission aluminium smelters

Using renewable energy as the source of the electricity used in aluminium smelters is the best way to improve the carbon footprint of the primary aluminium the smelters produce. By far. But eliminating the greenhouse gas emissions from this aluminium production would bring us closer to zero-emission smelters. I think this is possible.

Power generation represents the biggest way of improving the sustainability profile of aluminium. Best for the environment are hydropower-based aluminium smelters. Coal-based plants are the worst, and unfortunately, these outnumber the good ones.

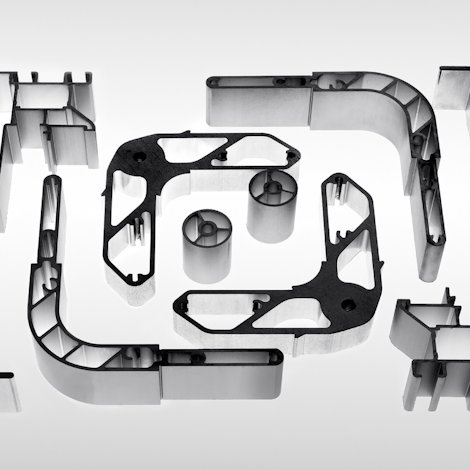

Still, all can improve, because all these smelters have the electrolysis process in common. Granted, direct emissions from electrolysis are on average only about one-tenth of those from the energy source, but they are significant.

So how can we eliminate these direct emissions and get closer to the zero-emission aluminium smelter?

Using inert anodes and aluminium chloride process

Lately, there has been a renewed interest in inert anodes. It is almost ironic that even back in Hall’s original patent for the Hall-Heroult electrolysis process from 1886, it is mentioned that inert anodes should be possible to use in the process within a rather short time. That “short” time has proven to be rather long.

The industry has spent billions on research and development and the testing of inert anodes over the last decades, but no solution exists. It is still regarded as one of the options though, toward lowering emissions from production.

Another is a chloride process in which the alumina is converted to an aluminium chloride that can readily be processed by electrolysis. The chlorination needs carbon, but the carbon as well as the chlorine might be recycled in a closed loop.

New technologies including bio-carbon use and carbon dioxide capture

Those are the most obvious new technologies. At the same time, we need to be open to the possibility that there may be other ground-breaking technologies still not identified, that can reduce the direct emissions from aluminium production and help us achieve our sustainability goals.

Other alternatives are to use bio-carbon in the anodes or to capture the CO2 and either utilize it for products or store it safely. The advantage of these two solutions is that existing Hall-Heroult smelters can still be used.

More collaboration in aluminium industry is a key factor

As long as the solutions are so unclear, it is important that the aluminium industry follows several paths to reduce or eliminate its direct CO2 emissions. There might not be a single “one size fits all solution” but a variety of solutions depending on local conditions of each smelter.

I strongly support and promote the trend of more collaboration within the aluminium industry. Tech development is so fast that it is difficult to be in the front in all areas, and we need to remember that other materials are our main competitors and not our peers.

If we can develop technology and solutions together with good suppliers, then the costs of these will come down and ensure implementation. The competing factor in the aluminium world will then be how good we are at implementing and using these new technology elements for the production of low-carbon metal.

Zero-emission aluminium smelters in future

How soon will we see a zero-emission aluminium smelter?

This is hard to say, but it will likely require years of research, followed by a demonstrator (typically a handful of production cells) and a proper pilot working under industrial conditions (comparable to Hydro’s Karmøy technology pilot) before anyone is ready to accept the risk of being the first to invest in a full-scale plant.