Aluminium design for e-car battery frames

Battery frames for electric vehicles come in all sizes and shapes. This flexibility is something you get with aluminium extrusions.

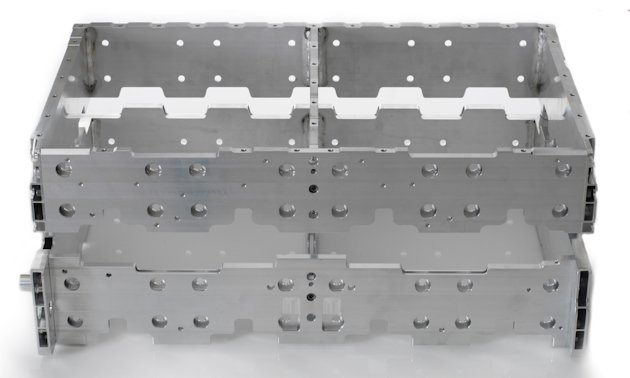

The main function of battery frames is to hold and protect the battery modules. By protection, I also mean that the frames have to be leak-free to make sure the battery modules and electronics are kept safe at all times.

Light weight matters, too, because this is going to affect the performance of the car.

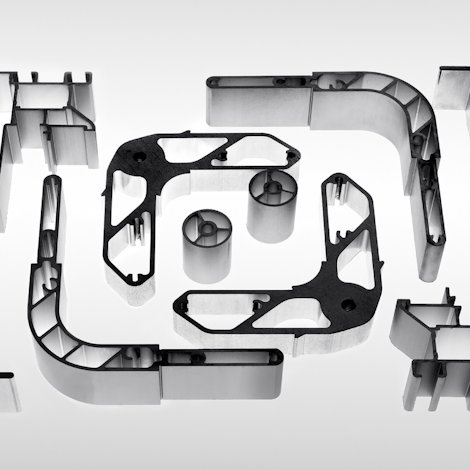

Smart designs with aluminium extrusions

People want to be able to drive longer distances with their electric cars, and today, this means more battery modules. And a bigger frame. So besides holding the modules in place and protecting them, the battery frame is now having to actually interact with the car body.

Big frames can impact the whole architecture of the car body. In some models, battery frames are as big as almost the whole floor of the car. This means they have to be integrated cleverly in the car structure. They need to interact with the body in the right way so that they provide the behavior you want with the whole car.

Modular and scalable frame designs

Smart designs using aluminium extrusions can simplify the assembly process and fixation of the individual battery modules. They also provide more energy absorption in case of a crash, compared with other materials and processes.

Other benefits are:

- Cooling. Structural floor panels can be designed to include integrated cooling channels to cool the battery modules

- Strength and stiffness. A frame made from extrusions provides great strength and stiffness to the entire car body while keeping weight to a minimum

- Design flexibility. Modular and scalable frame designs can easily be created cost effectively with extrusions

- Leak tightness. A completely leak-free frame can be achieved using extrusions and the right joining technology, such as friction stir welding

Design flexibility

OEMs are looking at different ways to solve these challenges.

Compared to two years ago, OEMs have refined their own design philosophies for these types of products. There is more maturity with what they want, how they can future-proof the frames.

I see extruded aluminium design as the best way for them to meet their needs. It is very easy to create modular design with extrusions, and with so much development going on with the electronics and battery modules, the platform concept design becomes relevant.