How we are communicating compelling stories with aluminium waste

Industrial waste is highly stigmatized, despite the decades of research and efforts that have gone into demonstrating safe and alternative uses. There is a disjunction between the economics, the legislative barriers, and the public’s perception. Our interest, as designers, is that by using these materials, like aluminium crusts, we can uncover the complexities behind their production and shift the perception that otherwise would hinder further developments.

ThusThat is a design and consultancy company focused on sustainable materials. We operate between creative and technical disciplines. We act as a bridge from the R&D lab to the public through the creation of compelling stories surrounding materials and technologies.

Besides our own designed objects using industrial waste and byproducts, we have collaborated with mining and metal companies, architects, artists, retail companies, and more.

We strongly believe that design is primarily a tool for communication. We make unusual objects, there is no denying this, and we are not naive, we know they are not scalable solutions. But that was never the point. We are not using waste because we are warriors of sustainability, but because we view design as a means to reveal stories behind the everyday – to challenge preconceptions surrounding a material.

These objects are often directly derived from working with scientists who themselves have uncovered real scalable solutions, but are obscured from the public eye. In this way, we translate ideas from the lab into tangible applications, and quickly. By doing so, we believe we can shift the desirability surrounding materials towards more sustainable options and drive incremental change.

Aluminium crust as a raw material

It has only been in the last year or two that we began working with aluminium metal on its own – and we love it. It is a forgiving material. Its softness allows it to be worked almost like hard wood, while benefiting from the properties of a metal.

We started with aluminium not long after having visited a smelter for the first time, when we caught a glimpse of the scale of aluminium production in its metallic form. We found this captivating. It was also there that we first saw the off-cut surfaces from the massive six-sides-sawn aluminium blocks they produce, off-cuts they colloquially referred to as the “crust.”

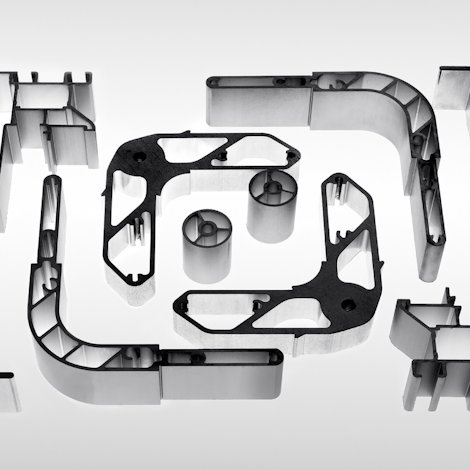

Our newest series is made from these aluminium crusts.

The crust benefits from being a uniquely thick sheet of formats up to four meters in length, so we are able to treat the aluminium almost like plywood in assembly and manufacturing, allowing its raw nature and strength to speak for itself.

The softness of aluminium

Aluminium is clean and forgiving, and it is light and strong, which allows us larger forms than we would normally do. It can have countless finishes. It can be cut, bent, hammered, polished, cast, welded, foamed, tapped, threaded, joined and more. We have only scratched the surface (pun intended) of what we will do with it, but we are mainly interested in using aluminium in a way that challenges how we think of it.

Our most common struggle with aluminium is also its value: its softness. If you try for a perfectly polished surface, you need to be ready for long nights of polishing, and many times of re-polishing from subsequent scratches, or some specialized outsourced expertise.

We have learned to work around this by letting the material hold its own in a more raw state, and by using a combination of specialized tools that act as semi-abrasives, essentially polishing and pre-scratching the surface such that later scratches do not appear. And of course, by using post-treatments such as anodization, or outsourced expertise with the appropriate equipment (which we now do).

Complex and dynamic aluminium industry

We are going to continue to work with aluminium in designs in unusual ways, mainly because we think the aluminium industry is a complex and dynamic one that requires continual unpacking, particularly in the ever-changing landscape of today.

Communicating the complexities around these spaces in a tangible way is a prerequisite of creating any pull from the public to justify the push from industry, research or otherwise.

We strongly believe in the importance of working with other experts and industrial partners as they hold the majority of the knowledge, experience, and, importantly, the contextual understanding. Our interdisciplinary way of working means we act as a glue between the fragmented stakeholders to uncover new threads and strategies in a space that demands dynamism.